Multilevel Energy Regulation&Energy Saving Subway HVAC unit

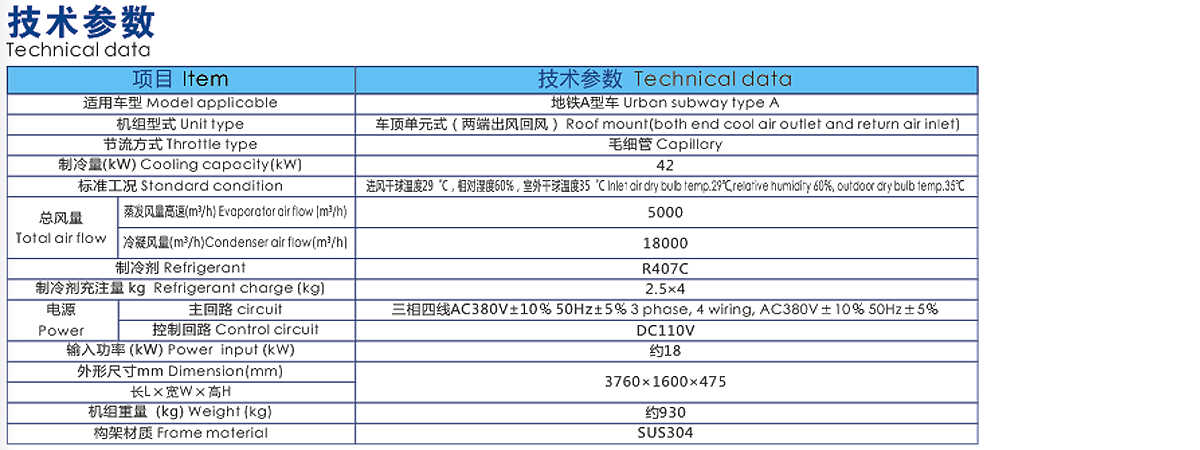

DL42-A型 | LD42-A Mode

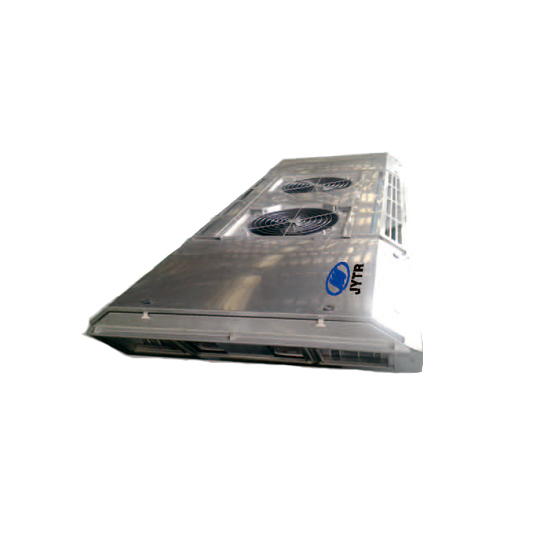

LD42-A series are HVAC units designed for subway in north China and suitable for type A subway. Each car has 2 roof mount units. With flat bottom, 2 cool air outlets and 4 return air inlets on both ends, the unit is connected with integrated control cabinet in electricity distribution room by electric connector. The cool air outlet and return air inlet of the unit are sealed by joint strips with the main air duct and return air duct of the vehicle roof. Treated air is blown into vehicle through air duct and cool air outlet.

With 4 hermetic horizontal scroll compressor, R407c refrigerant and capillary throttling, each LD42-A has 4 independent cooling recycling units. 1~4 compressors can be started to achieve 25%, 50%, 75%, 100% cooling capacity, by judging of indoor load condition through signals of sensors placed on return air outlet and fresh air inlet of the unit. Energy saving and accurate temperature control can be realized by starting only 1 condenser fan, when 1 or 2 compressor is working. 4 compressors will be delay started in order to lower the startup current to the minimum level. CPU will take records of total runtime for each compressor, and balance compressor lifespan by starting the shortest one in runtime. Integrated control cabinet is used to achieve auto, manual and centralized control of the units.

All components of LD42-A subway HVAC units: hermetic scroll compressor, evaporator, condenser, capillary tubes, gas-liquid separator, drier, filter, axial fans, centrifugal blowers form 4 independent cooling system. Electric regulator and temperature sensor are placed in both return air inlet and fresh air outlet to adjust airflow of fresh air and return air as needed. Filter is placed in fresh air outlet, easy to take down and do cleaning. Electrostatic cleaner is installed in front of evaporators, to achieve electrostatic dust precipitation and sterilization of mixed air. All components are assembled in a chamber made of SUS304 stainless steel. Silver brazing is applied for tubes and components connection. The cool air outlet is placed in the front of the unit, and 4 fresh air inlets are placed at 2 sides of the unit. Condensing water can be drained separately, or concentrate drained with connectors. The unit power cables are introduced into rare of the unit through connector.